Are your HMI Alarm Screens overwhelming your operators with information? Too many alarms can lead to information overload and operators eventually start to ignore them.

Alarm screens that display every field alarm, diagnostic alarm, EVENT, and SOE can make it difficult for operators to identify alarms that need attention and possibly immediate action.

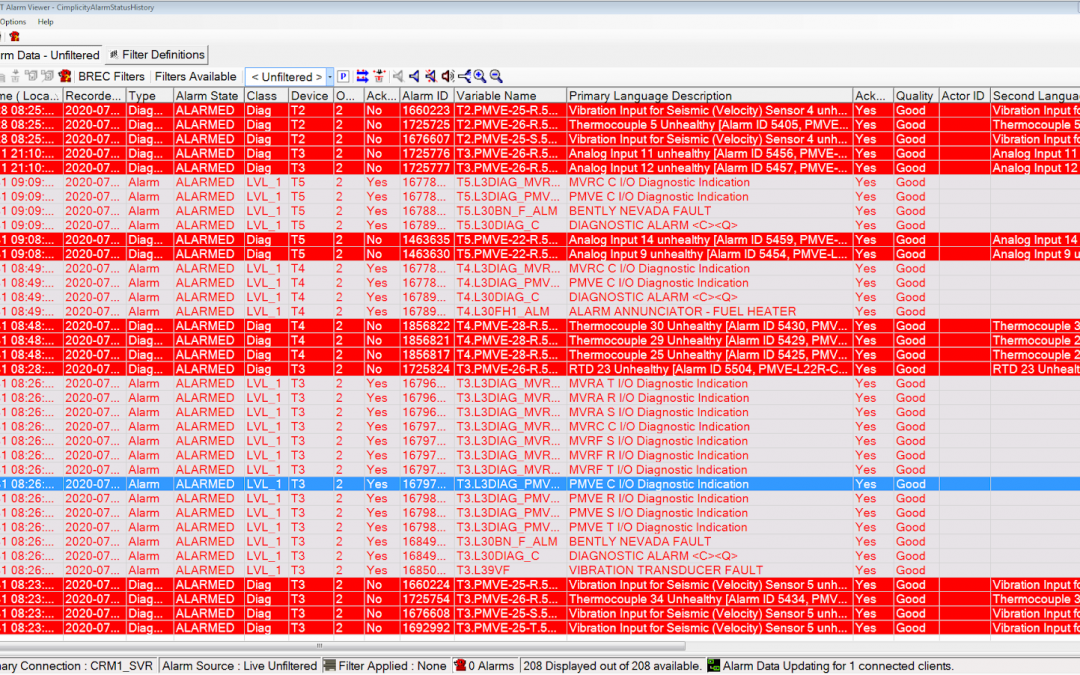

It is not uncommon to see HMI alarm screens flooded with alarms and events, to the point that not all the information can be displayed on a single viewable screen. If this describes your HMI alarm screens, then you may want to consider: 1) retraining your operators on alarm screen management, and/or, 2) you may have a large number of actual control system issues that need to be addressed.

HMI alarm screens are critical to plant operations. If plant operators are flooded with too much information, then they may be creating blind spots and potential hazards within your plant. It’s not difficult to set up your HMI alarm screens so that your operators can quickly identify and address alarms and events as they appear.

In this article, we will provide some tips on how to better manage your HMI alarm screens.

Identifying an Alarm Management Problem

Do you have an alarm screen management problem? Does your alarm screen constantly display a “wall of red”? If your operators are not able to quickly differentiate between critical alarms, non-critical alarms, or normal event notifications, it is important to recognize that as a problem.

The first place to start is to realize the difference between various types of alarms and events that populate your HMI alarm screen. Alarms can come from field devices or malfunctioning control cards. Alarms also have various levels of severity (Lvl_1,2,3), as determined by the OEM.

Events provide information to the operators as the turbine is changing states, such as during a unit startup. Events also provide a lot of useful troubleshooting information if the equipment is not operating correctly or after a Unit Trip occurs.

However, event notifications can flood an alarm screen very quickly and make it difficult to identify alarms. Operators’ number one priority is to protect plant personnel and equipment by operating the machinery in a safe manner. Being able to effectively use your HMI alarm screens to quickly identify equipment issues is a critical skill for every operator.

Implementing an Alarm Screen Management Process

Your goal is for plant operators to be able to use the HMI Alarm Screen to quickly identify and stop equipment issues, to protect plant personnel and equipment. An alarm screen management process will establish guidelines for operators to help reduce the number of alarms and events displayed on the alarm screen, as well as put a system in place to actively troubleshoot and correct alarms that need attention.

Here are a few tips for alarm screen management to get you started:

- Designate one HMI per unit and filter the alarms on that HMI alarm screen to show only for that unit.

- Adjust your alarm column layout to reduce the amount of information displayed on the alarm screen. This allows operators to quickly glance at and process the alarm information shown.

- The alarm screen filter function can remove EVENTS and SOE (Sequence of Events) notifications that can draw attention away from alarms. These event notifications are important and can be filtered onto a separate HMI and/or under a different filter.

- Utilizing the “Normal_Alarms” filter allows operators to quickly acknowledge and reset inactive alarms.

- Each (real field device) alarm should be logged in a logbook, and required actions documented in a work order. At the end of a turbine run, after the alarms are added to the logbook, the alarms should be acknowledged and cleared. This will keep your total alarms and events count down to a more manageable level.

Give Your Control Room Operators the Training They Need

Establishing an HMI alarm screen management system is not difficult, and it will help your operators respond to real-time alarms in a more effective manner. TC&E field engineers can help establish an alarm screen management system, address any longstanding alarm issues, and give your operators the tools they need to effectively monitor the plant equipment. Get in touch with our team today to learn more about how our Field Engineers can help.

Watch Our Webinar & Videos

Watch Our Webinar & Videos