LCI DIGITAL FRONT END RETROFITS:

While performing annual maintenance can keep your Original LCI operating reliably, the OEM has discontinued manufacturing the LCI Control Components, resulting in a high-risk single point of failure. Unless you have a complete set of spare components, upgrading to the latest technology and available components may make sense for your plant.

TC&E and TMEIC have partnered to offer a Digital Front End (DFE) upgrade that is more

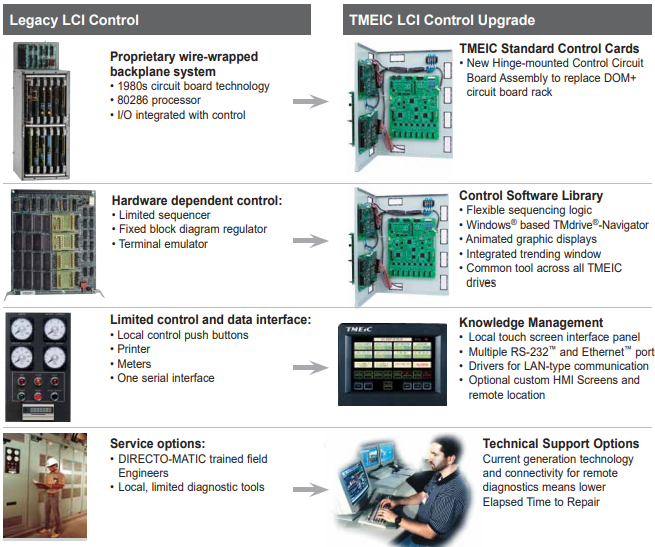

Legacy LCI drives have provided reliable service for almost 25 years. To keep that record intact, TMEIC has developed a control upgrade for Legacy Gas Turbine Static Starter Systems, while preserving the existing power conversion hardware. In addition to extending the product life, this modernization program provides significant functional enhancements plus a system condition and capability assessment of your static starter system.

Benefits of a TMEIC Digital Front End upgrade:

-

Reduced number of circuit boards

-

Color touch-screen Operator panel in control compartment door

-

Extensive diagnostics and self-test capability

-

External control interface through TMEIC TMdrive-Navigator Software

-

Voltage Feedback offset nulling is eliminated

The TC&E/TMEIC LCI Assessment and Modernization Program provides drive system investment protection through well documented engineering procedures for assessment and preventive maintenance of switchgear, magnetics, controls, and power converters. Complete project management equals peace of mind.

Control Modernization for Legacy LCI Drive Systems

Read the attached document for further understanding.

Control Modernization for Legacy Gas Turbine Starter Systems TMdrive-LCI-DFE (Digital Front End)

Read the attached document for further understanding.

Reliability

Using the latest technology, components, and lessons learned through decades of experience, TC&E can ensure complete reliability for both start-up and continuous operation.

Affordability

Spending good money where it makes the most difference! We understand that O&M budgets are shrinking, so we work with the plants to understand where and when to repair, replace, or upgrade for maximum return.

Efficiency

This is the key to success in today’s competitive power markets. Heat Rate, Capacity, Start-Up, and Maintenance Costs are critical to the success of aging power plants.

Longevity

Aging systems can continue to provide reliable service for many years to come with the proper service, maintenance, and repairs. Push your upgrades out 5-10 years with confidence.

Success Story

TC&E has always provided a high level of expertise and detail on our site—most notably, custom-tailored projects to reduce parasitic load during the off-peak seasons using logic and controls.

Partners - We Partner with some amazing and marquee industry partners.

Watch Our Webinar & Videos

Watch Our Webinar & Videos