Performing preventative maintenance (PM) on gas turbine static start systems is crucial to ensure a plant’s ability to consistently start up their equipment. The benefits of a proper PM plan include increased equipment longevity and the reduction of forced outage events. Understanding these systems and the necessary maintenance involved can help plant managers and personnel to make informed decisions regarding the need for equipment upgrades.

While upgrading outdated controls hardware associated with the Load Commutated Inverter (LCI) can be very beneficial, upgrading more robust components like a disconnect switch is likely unnecessary when they are properly maintained. Making more informed decisions and reducing sudden equipment failures will save a plant’s maintenance department time, money, and stressful conversations with plant management.

In the article, we’ll discuss one aspect of PM on a set of static start disconnect switches to help ensure continued and safe operation of a gas turbine static start system.

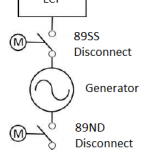

LCI Switches 89SS and 89ND

Limit Switch Failure on Disconnect Switches

The components on a static start system that are most often overlooked are the disconnect switches. These switches, the 89ND (neutral disconnect) and 89SS (static start disconnect), make it possible for LCI to motor the generator during a gas turbine start, and also to disconnect the LCI from the generator upon reaching 90% of rated turbine speed during startup. Many of these disconnect switches have been in operations between 10 and 20 years, and switching mechanics can fail if unattended.

A common failure point is the limit switches that are located on the disconnect switches. These limit switches provide feedback to the turbine control system to indicate whether the 89SS/ND is in the Open or Closed position. The position status of the disconnect switch is a critical operating and safety component of the static start system. The older style limit switches, particularly those provided by Powergear, have plastic components, which break down over time. Once those limit switches lose the ability to provide an Open/Close indication to the turbine control system, this can result in a forced outage, substantial damage to the LCI, and can also present a safety issue for plant personnel.

Monitoring and Testing

Monitoring and replacing these limit switches is not a complicated task, once you’re familiar with the process. An experienced field engineer can help to train your plant instrument technicians to properly replace and test these limited switches. It is the offline testing process that is generally the missing piece of a solid PM plan. Testing these critical components for the first time on an operating turbine is a dangerous practice. Offline testing involves providing power to the 89SS/ND, sending force signals to actuate disconnect switches Open and Closed, then monitoring the limit switch position feedback from the control system.

How TC&E Can Help

Preventative maintenance is just one service TC&E can help with. We call this our Clean and Inspect service. TC&E offers Clean and Inspect services on both the LCI and the Exciter systems, which we recommend to be performed annually. TC&E can work with plant personnel to provide equipment specific training on the overall system as well as the PM performed during a Clean and Inspect.

Give TC&E a call if you have questions regarding PM planning, or whether you should consider upgrading your equipment instead of continuing to maintain it. We can review OEM recommendations and upgrade options for aging equipment. We are also knowledgeable of a majority of the less expense non-OEM upgrade alternatives. Perhaps the best solution is a robust preventative maintenance plan that will save you money and time, and keep you operating trouble-free for years to come. TC&E will give you an unbiased perspective on the best course of action for managing the life of your control systems equipment.

Contact us today for help with building an annual maintenance plan for your LCI system.

Watch Our Webinar & Videos

Watch Our Webinar & Videos